High Precision Grinding of Hard Tooth Surface Spur Gear Using Machine Tools M3 18T

| Categories | Spur Gear |

|---|---|

| Brand | MR.SPROCKET |

| Model | M3 18T |

| Standard | ISO |

| Steel | C45/STEEL/42CRMO |

| Bore | Finished bore/Pilot bore |

| Hardeness | HRC40-50/NO/Carburizing and Quenching |

| Surface treatment | No/Zinc-Plating |

| FOB port | Shanghai/Ningbo |

| Terms of Payment | T/T |

| Update Time | Apr 22,2025 |

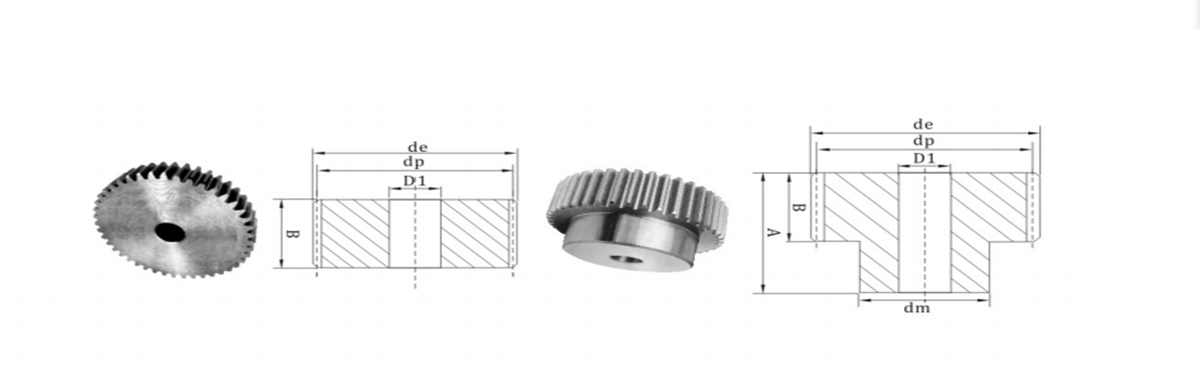

The drawing of Spur gear

The more information about GEAR

Spur gears are machine parts that convert rotational motion and transfer mechanical energy from one shaft to another. They are mainly used for gears with a constant transmission ratio and a small axial distance of the shaft.

They are available in modules M1 to M8. Gears are designed with or without hubs (flat wheels).

We offer gears with straight teeth and a mesh angle of 20°.

Caution

The spur gears in a particular gear must have the same module.

For more complex and precise requirements, direct use of special gears designed and manufactured by specialist suppliers is required.

Spur gear application field

Spur gears are designed for general use in mechanical engineering.

The standard spur gears we offer are mainly used for basic and simpler structural and technical solutions in conveyors, presses, gearboxes, woodworking machinery, agricultural machinery, and of course for many other applications.

PRODUCTS SUPPLIED IN MR.SPROCKET

The normal general delivery time is 30 days, which is the longest among all shipping methods. But if the customer's delivery time is not urgent and the goods are heavy, it is usually transported by sea. Because sea freight is the cheapest shipping method

The general time for air transportation is 7 days, but usually the goods are around 100KG, and we are heavy goods. If it is too heavy to be shipped by air, the shipping cost will be high.

International express delivery time is generally 7 days. The weight of the goods is generally within 45KG, and our samples are generally transported by international express.

Mr.Sprocket have a Professional,Energetic and Responsible team.

If you want to know more details, please kindly contact our sales, we will reply you at the first time.

- Loading...

- HOW TO MAKE A SPROCKET?MR.SPROCKET is a professional, Energetic and responsible company. Our can offer kinds of transmissions products: Roller Chain,Sprocket,Gear,Roller Chain;Pulley; Bushing and ETC. Today we will introduce the production process of sprockets.

- HOW TO USE A SPROCKET?It is widely used in mechanical transmission in chemical, textile machinery, food processing, instrumentation, petroleum and other industries.

- Tel

- *Title

- *Content